RECOMMEND SOLUTIONS

RELATED PRODUCTS

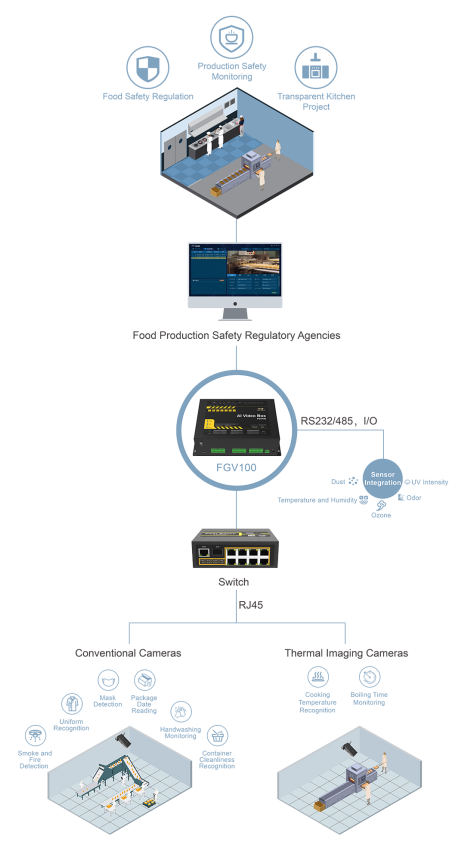

Four-Faith AI Intelligent Video Box + Sensor Cloud Platform, Pioneering a New Model of Intelligent Supervision For Food Safety

Date:2024-04-07 17:42:22

Background:

Food, as an essential element for human survival, is crucial for everyone's health and the sustainable development of society. Ensuring safe and healthy food production is a top priority for regulatory agencies and a collective concern in modern society.

Industry Pain Points:

Difficulty in Managing Production Processes:

Scattered production sites and dispersed workshop locations lead to challenges in supervision, resulting in low efficiency and blind spots.

Difficulty in Detecting Violations:

Lack of transparent supervision over various aspects of food processing (e.g., ingredients, personnel, utensils, disinfection) hampers the timely detection of irregularities.

Challenges in Preventing Safety Accidents:

Without transparent production and efficient supervision, it's difficult to implement intelligent warning systems, resulting in regulatory authorities and business managers being unable to promptly identify safety hazards during production.

Solution Overview:

To enhance food safety production efficiency and safeguard consumer health, Four-Faith proposes a novel food safety production solution. This comprehensive approach integrates advanced sensing, image recognition, algorithm models, edge computing, intelligent analysis, and AI alert technologies. It aims to ensure the safety and quality of food production by continuously monitoring various stages of the production process, promptly identifying, and addressing potential safety hazards, and effectively preventing food contamination and improper operations.

The solution utilizes the Four-Trust AI Smart Gateway to interface with frontend sensing devices, IPC devices, etc., to analyze collected data, images, etc., perform data analysis, image recognition, edge computing, and then push detected abnormal data, violations, abnormal production operations, and other events to the Four-Faith Sensor Cloud Platform. The platform records, stores, and manages detailed information about each abnormal event and sends alert messages to various supervisory departments, management departments, responsible persons, administrators, etc.

This solution leverages advanced AI supervision methods to achieve intelligent and intelligent levels of food safety production supervision and management work, making food safety production supervision and law enforcement work traceable and evidenced, with a 360° comprehensive supervision and evidence collection capability, to achieve more authoritative, efficient, and legally effective regulatory implementation effects.

System Functions:

Unified Supervision:

Food production plants and production workshops often have multiple points distributed in different locations, which can be uniformly summarized through the platform for production supervision.

Mask Detection:

On food production lines, employees need to wear masks to prevent saliva or bacterial contamination of food. Real-time detection of whether employees are wearing masks correctly helps ensure the hygiene quality of food.

Environmental Parameter Collection:

Install various environmental sensors in the production operation area, including temperature sensors, humidity sensors, air quality sensors, etc., to collect real-time data on environmental comfort. These data will be used to assess the quality of the production environment and take necessary measures to maintain the cleanliness and hygiene of the production environment.

Violation Detection:

We will install AI cameras to detect violations such as not wearing masks, not washing hands, entering, and exiting passageways in the wrong direction, and not wearing work clothes. AI cameras will detect these violations through image recognition technology and immediately issue alerts so that staff can take corrective action promptly.

Disinfection Condition Detection:

We will use relevant sensors to detect disinfection conditions, such as disinfection of production equipment, workbenches, etc., to ensure that food production equipment has been adequately disinfected before operation.

Data Reporting:

We will establish a complete data reporting module to better monitor the food production process. Through the analysis of data summary reports, we can promptly identify potential issues and take corresponding improvement measures.

Mask Detection:

Real-time detection of whether employees are wearing masks correctly helps ensure the hygiene quality of food.

Work Clothes Detection:

The system can monitor in real-time whether employees are wearing work clothes as required to ensure hygiene and safety during the food production process.

Stain Detection:

Automatic detection devices can promptly identify and handle stains on production equipment, work surfaces, production vessels, etc., to ensure food safety.

Handwashing Detection:

Through intelligent detection, ensure that employees have cleaned their hands before handling food.

Video Surveillance:

Through the video surveillance system, observe and record the various stages of food production in real-time, standardizing the entire food production process.

Anomaly Alerts:

Monitor production operations 24 hours a day, and when anomalies occur, promptly alert relevant personnel, including SMS alerts, web alerts, email alerts, app alerts, DingTalk alerts, etc.

Solution Advantages

AI Smart Supervision, Standardizing Transparent Operations

The solution combines "Intelligent AI Visual Image Analysis Technology" with the Four-Trust Sensor Cloud Platform to achieve real-time monitoring and complete process recording of the dressing status of factory personnel and the hygiene environment. Through intelligent identification of violations and anomalies by the system, immediate alerts are issued on-site to ensure the safety and hygiene of the production process, safeguarding consumer health.

Intelligent Operations and Maintenance Platform, Reducing Management Costs

By automating data collection and analysis, the solution enables remote supervision and intelligent management of food production enterprises, improving factory management efficiency, significantly reducing enterprise maintenance costs, and ensuring factory financial security.

Visualized Supervision, Real-time Alerts 24/7

Utilizing the Four-Trust Sensor Cloud Platform to achieve visualized supervision of the factory's production process, enabling a comprehensive upgrade of on-site "perception, monitoring, identification, capturing, and alarming." Timely alerts are issued before accidents occur, reducing safety hazards and building a production safety "protective shield" for operators.

Product Recommendation

AI Edge Intelligent Video Box

FGV100 is an AI Edge Intelligent Video Box specifically designed for IoT scenarios. It can connect high-definition cameras and IoT sensors simultaneously, enabling on-site data collection of temperature, humidity, rainfall, water level, flow rate, wind speed, and more. Additionally, it can interactively control valves, gates, and switches, seamlessly managing complex on-site equipment interactions. With just one device, it can easily monitor and control various elements.

Internet of Things RTU Network Camera

The Internet of Things RTU Network Camera, as part of the intelligent IoT monitoring product line, is designed specifically for industrial-grade IoT application environments. It utilizes 4G/5G networks to provide users with wireless, long-distance, and ultra-low-latency transmission of high-definition videos. Additionally, it can collect and analyze various types of sensor data accessed through its built-in high-performance industrial-grade MCU. Moreover, it performs AI image recognition functions at the edge, achieving protocol interoperability and unified management.

The Internet of Things RTU Network Camera, as part of the intelligent IoT monitoring product line, is designed specifically for industrial-grade IoT application environments. It utilizes 4G/5G networks to provide users with wireless, long-distance, and ultra-low-latency transmission of high-definition videos. Additionally, it can collect and analyze various types of sensor data accessed through its built-in high-performance industrial-grade MCU. Moreover, it performs AI image recognition functions at the edge, achieving protocol interoperability and unified management.

TAGS: AI Intelligent Video Box Sensor Cloud Platform Intelligent Supervision [Previous Page]

Previous Page:5G+ Smart Factory Data Collection and Monitoring Solution

next page:Factory Security Surveillance Project