5G has huge disruptive potential in meeting the basic network requirements of manufacturing operations. This industry, known as Industry 4.0, is now being digitally transformed by the evolving Industrial Internet of Things (IIoT).

Since 5G uses a shorter (millimeter wave) frequency, between 30GHz and 300GHz, and a small part of it will be used by mobile networks, it has excellent features. Compared with 4G, 5G provides lightning-fast data speeds, up to 100 times faster, extremely low latency (1 millisecond), and the number of connected devices per unit area is much larger. However, to take full advantage of the benefits provided by 5G, a new set of network infrastructure is required, including mesh networks, phased array antennas, and cloud computing.

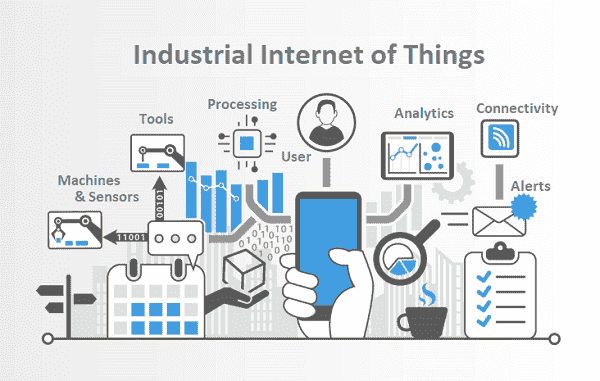

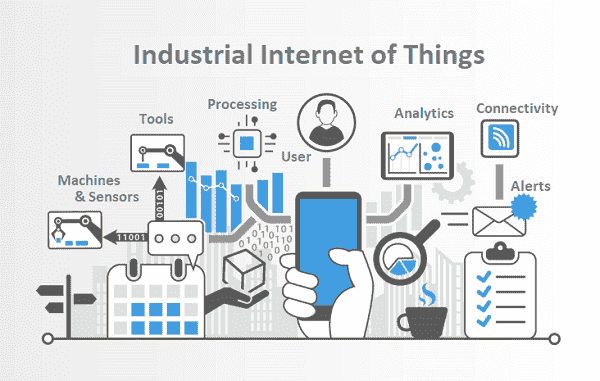

Industrial Internet of Things

The intelligent interconnectivity of all digital devices used in factory floor automation and supply chain management, starting with measuring equipment, programmable logic controllers (PLCs) and their industrial applications, all the way to intelligent logistics, can be called IIoT. This interconnectivity is supported by modern technologies, including edge computing, cloud computing, machine-to-machine (M2M), 3D printing, advanced robotics, big data, RFID technology, and cognitive computing. At present, many companies involved in technological innovation are leading the fourth industrial revolution.

There are several requirements for successfully delivering an IIoT solution. First, a tiny software-defined radio (SDR) or RFID chip is required. It must be low cost and require very low power from sensor batteries, because most of their applications will range from deployment in agriculture, factory floors, and hard-to-reach places, such as oil and gas fields, automobile manufacturing, and logistics operations. This allows seamless wireless communication in unlicensed industrial frequency bands, usually 900 MHz.

There are four main levels of the Internet of Things

1. Functions and requirements of the Internet of Things

As the industry rapidly shifts to IoT solutions, the need for flexible resources with optimized costs becomes imperative. Cloud computing provides shared computing resources and centralized management and monitoring, and provides computing services through networks and servers, central storage, advanced analysis, and business intelligence. It uses these technologies to process big data, perform machine learning, and use data warehouses for business logic and operational management. On the contrary, edge computing relies on processing data, and data is generated through decentralized computing infrastructure located at the "edge" of the network. Faster networks like 5G enable edge computing to process large blocks of data in real time and perform tasks such as optimization at the source.

This capability can only be used with the support of a powerful network that can communicate with a large number of devices. To help achieve this goal, many different network protocols are used to transfer data between network nodes, including:

● Message Queue Telemetry Transmission (MQTT)

● Advanced Message Queuing Protocol (AMQP)

● Restricted Application Protocol (CoAP)

● Modbus and OMF

This is where the main features of 5G networks come together:

● Enhance ultra-reliable low-latency communication (eURLLC)

● Large-scale machine type communication (mMTC)

● Enhanced Mobile Broadband (eMBB)

2. Benefits of the Internet of Things

IIoT promises to bring some benefits in one of the most critical areas in any industrial environment: personnel and process safety.

With the enhanced monitoring of all connected IIoT sensors sharing key safety parameters with each other, the possibility of accidents is significantly reduced. Wearable devices can play a greater role in disasters by accurately locating the exact location of employees in distress and protecting their welfare.

Security is another area where IIoT benefits, whether it is cyber security or physical monitoring of manufacturing sites. This also includes eliminating human error, which is the most common cause of data and network leaks.

3. Due to IIoT

Provides manufacturers with the ability to automate a wide range of processes, so improving operational efficiency is another area where productivity can increase. This is achieved by optimizing maintenance and labor-related costs, and making data-driven decisions based on operational intelligence insights provided by all connected manufacturing functions.

IIoT also helps achieve operational reliability by accommodating all specific industrial applications from different original equipment manufacturers and suppliers, and standardizing in all processes.