RECOMMEND SOLUTIONS

Four-Faith Casting Machine Remote Management Solution

Date:2021-09-23 09:14:01

Background

In recent years, with the rapid growth of the industrial market and the scale of the automobile market, the development of the casting manufacturing industry also ushered in a good prospect. Taking the casting machine as an example, the stable and reliable operation of the casting machine is an indispensable condition for the completion of industrialization 4.0 and the automobile industry.

Pain Point

1. High labor costs, low work efficiency

2. Equipment production management level is low, unable to meet the existing demand

3. Unable to achieve the real-time monitoring, failure cannot be fixed at the first time

Solution Introduction

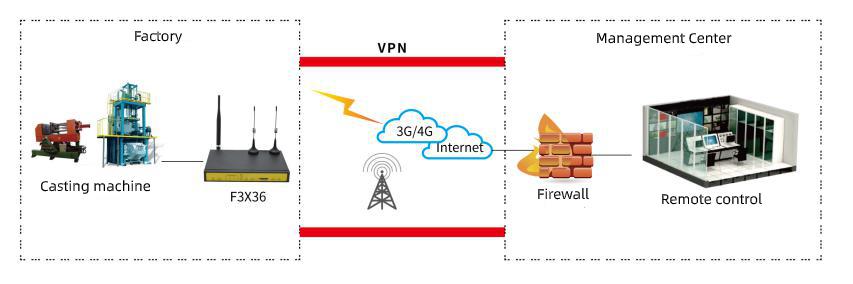

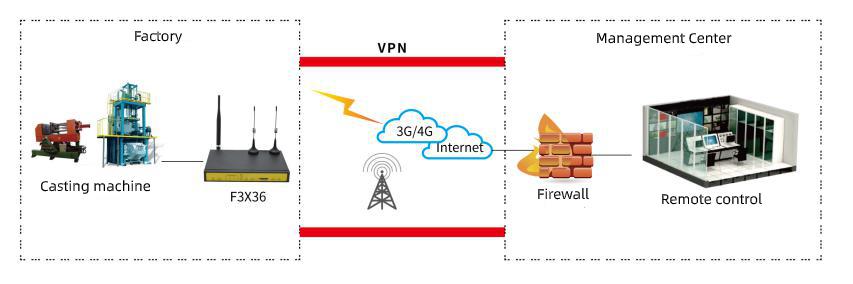

Four-Faith casting machine intelligent monitoring solution combines with the remote intelligent management system, IoT technology, and maintenance services. Manufacturers or service providers can remotely control the casting machine in different regions, provide remote service such as product upgrades, device alarms, etc.

The casting machine is mainly composed of motors, various mechanical equipment, and a station control system. The intelligent monitoring system of casting machine can be divided into three layers: acquisition terminal, communication terminal, and monitoring center.

1.Acquisition Terminal

Through the PLC controller of the on-site control cabinet can achieve the fast acquisition of real-time data of the casting machine such as pressure, temperature, pressure, and speed.

2.Communication Terminal

The communication terminal is composed of Four-Faith industrial router F3X36. F3X36 network port is connected to PLC, establish the VPN channel to connect the monitoring center through the carrier's network. Providing a data channel for the monitoring center to access acquisition terminal, helps the monitoring center collect and obtain data remotely.

3.Monitoring Center

The monitoring center is the interface between the Internet of Things and users. It is combined with industry needs to achieve the intelligent application of the IoT. Real-time data dynamic display, abnormal status automatic alarm, and alarm information will be pushed to mobile phone SMS or mobile phone APP.

Solution Value

Real-time and Effective Device Management

Through remote monitoring of the platform, the running status of equipment can be grasped in real-time, and faults can be dealt with timely and effectively, which greatly reduces the occurrence of high risks and high costs caused by equipment failures and maintenance.

System Management and Optimization

Through the operation and fault monitoring of system equipment, the whole system can achieve the integrated management and optimization of safety, high efficiency, and energy-saving.

User Service Improvement

Through the real-time alarm of equipment failure, Four-Faith can provide users with the best service in time and reduce the huge loss caused by equipment failure and maintenance.

Equipment Value Enhancement

The application of the Internet of Things, big data, and artificial intelligence systems has greatly enhanced the added value of enterprise equipment and product quality.

TAGS: Casting Machine [Previous Page]

Previous Page:Four-Faith Industrial Robot Remote Monitoring System Solution