RECOMMEND SOLUTIONS

Four-Faith CNC Machine Remote Monitoring Solution

Date:2021-09-24 16:37:16

Background

CNC machine is a set of machinery manufacturing, computer, hydraulic, sensing, information processing, optical, and mechanical technology in one of the electromechanical integration products. With CNC machine are widely used in industrial production, CNC machine and CNC technology has become the core of the manufacturing industry.

Pain Point

The uneven standards of equipment operators, increase maintenance costs

Troubleshooting after a fault occurs takes a long time and is difficult to maintain

Untimely information, dissymmetry

Solution Introduction

Because of the complexity of CNC machine and the limited manpower reserve of enterprises, equipment maintenance must rely on external forces. Four-Faith in-depth understanding of the needs of CNC machine manufacturers, to provide CNC machine remote equipment monitoring and maintenance solution.

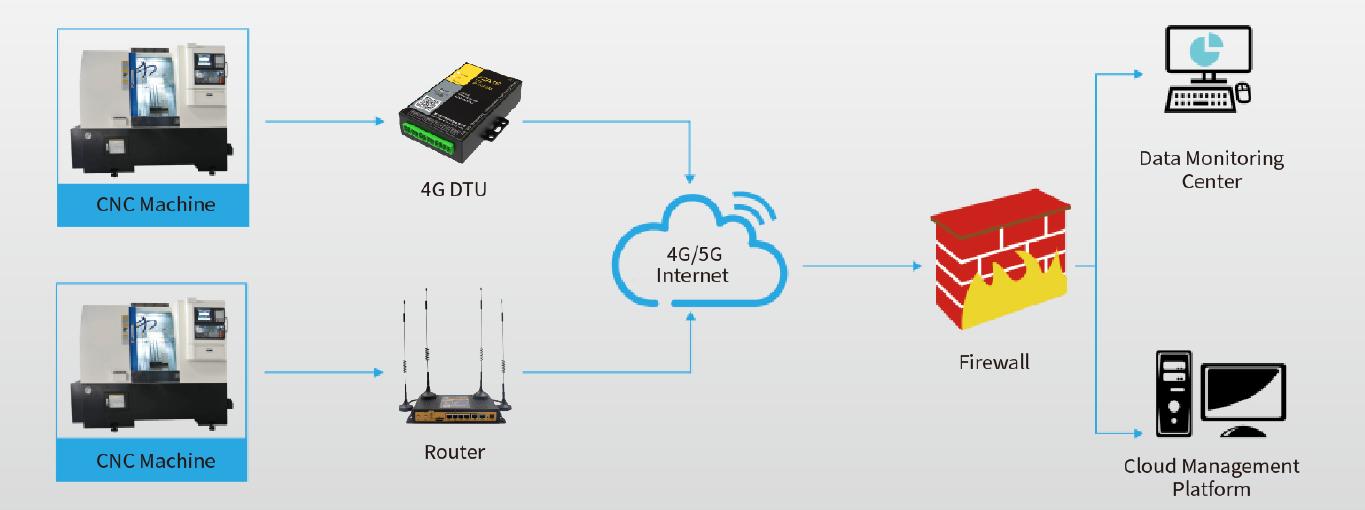

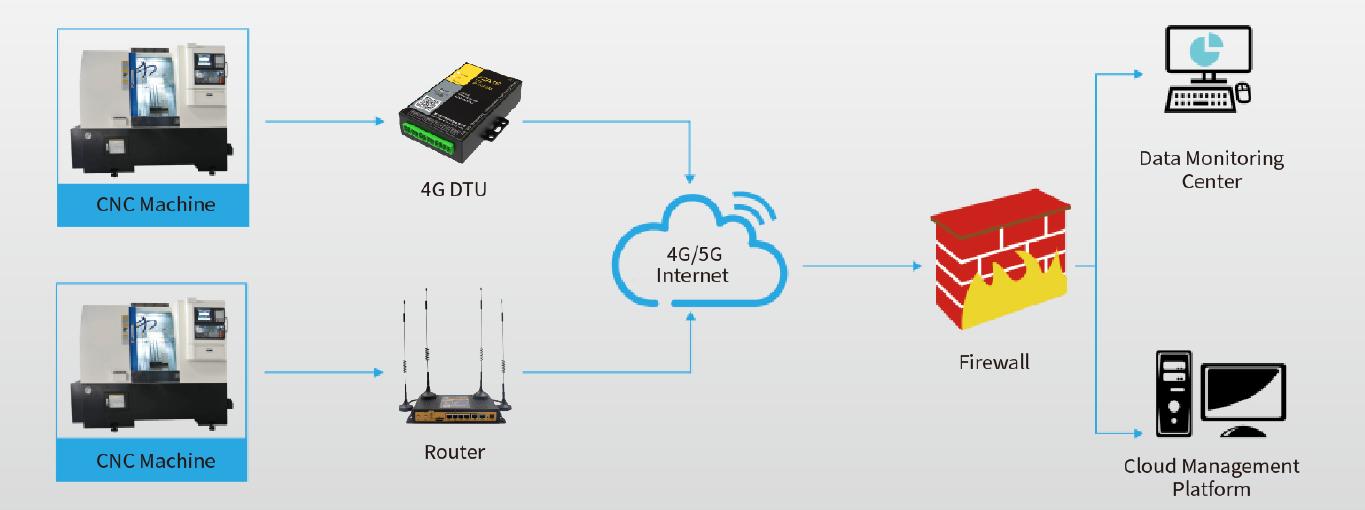

Solution using Four-Faith industrial 4G DTU and industrial router to achieve the equipment manufacturer's technical service center creates the wireless networking with the CNC machine through the DTU and routers to provide the stable 4G transmission channel, transfer the data of CNC machine operation and processing status to the technical service center in the real-time, provide remote management of on-site devices, and data, monitor the status of CNC machine in the real-time, infrastructure to achieve the real-time management of the CNC machine, alarm the mis operation and remind the regular maintenance to the control center. Realize the advanced service, reduce problems, convenient maintenance. Using the remote mechanical diagnostic and service system can greatly improve the management efficiency of CNC machine manufacturers and can make CNC machine manufacturers and users establish a long-term and close cooperative relationship, creating new commercial value.

Advantages

1. Real-time Monitoring of CNC Machine Operation Status

Data such as the status of the communication port of the CNC machine, the name of the program currently transmitted, and the progress of transmission are transmitted in real-time to provide key equipment data for factory users.

2. Remote Maintenance to Reduce Operating Costs

Remote maintenance for each CNC machine, remote diagnosis, remote control, automatic update and download of the system software, information transmission and other functions. Operation & maintenance personnel can timely solve problems without going to the site.

3. Trouble Diagnosis Analysis

Through the collection and transmission of anomaly and fault information, using remote diagnosis, analysis, remote service for customers to solve simple problems, reduce the number of unnecessary on-site services. Use data analysis to analyze the operation parameters of CNC machine and provide data support for the new generation of products through big data analysis.

4. Increase the Quality of User Experience

Solve devices problems in time, improve work efficiency and customer experience.

5. Fault SMS Notification

In case of any abnormality or failure during the operation of the CNC machine, it can give early warning in time and remind the relevant personnel of customers to deal with it through the platform or SMS, to improve the response efficiency of after-sales service.

6. Cloud Platform Remote Management

Supports cloud management platform for centralized management and remote monitoring and maintenance of transmission terminal devices.

Solution Value

For CNC machine users:

Achieve predictive maintenance, find potential trouble early, reduce machine downtime, prevent unexpected accidents, and improve productivity. When a hidden fault is found and the machine cannot be shut down, the user can control the machining of the CNC machine under the guidance of the remote diagnosis and service system to minimize the loss.

Transfer the specialized knowledge of CNC machine manufacturers to CNC machine operators and maintenance personnel to maximize the utilization of CNC machine.

Reasonably predict the life of CNC machine so that CNC machine in the quality and production of the condition to extended service.

For machine tool manufacturers and maintenance companies:

Reduce maintenance service personnel and costs.

Easy to use the CNC machine quality tracking, find the weak links, constantly improve the quality of CNC machine.

Manage the condition of devices to achieve the organic integration of post-maintenance, planned maintenance, and predictive maintenance.

TAGS: CNC Machine Manufacturers Industrial Router [Previous Page]

Previous Page:Four-Faith Casting Machine Remote Management Solution

next page:Four-Faith Air Compressor Remote Monitoring System