RECOMMEND SOLUTIONS

RELATED PRODUCTS

Four-Faith 5G Industrial Routers Empower 5G Full-Connected Factory Construction

Date:2023-07-17 16:37:53

Background

5G, as the forefront of "new infrastructure," bears the responsibility of driving the transformation and upgrading of the national economy, promoting the deep integration of the real economy and the digital economy, and meeting the high-quality communication service needs of various industries.

With the continuous evolution of 5G technology, industries across the board are demanding higher reliability and determinism from networks. 5G LAN, as one of the key features defined in the 3GPP R16 standard, exhibits excellent performance in network deployment, network determinism, low latency, high bandwidth, and data security. It possesses the characteristics of flexible network formation and is gradually becoming one of the important technologies that empower the flourishing development of vertical industry applications.

Pain Point Analysis

Traditional production lines rely on wired transmission, resulting in low efficiency in line changeovers.

The decentralized control of multiple processes leads to high defect rates, low efficiency, and high latency.

Headquarters face challenges in managing and operating branch plants, preventing centralized operations.

Factory energy consumption does not meet the company's dual-carbon strategy.

Internal data security management within the factory is challenging.

Solution Introduction

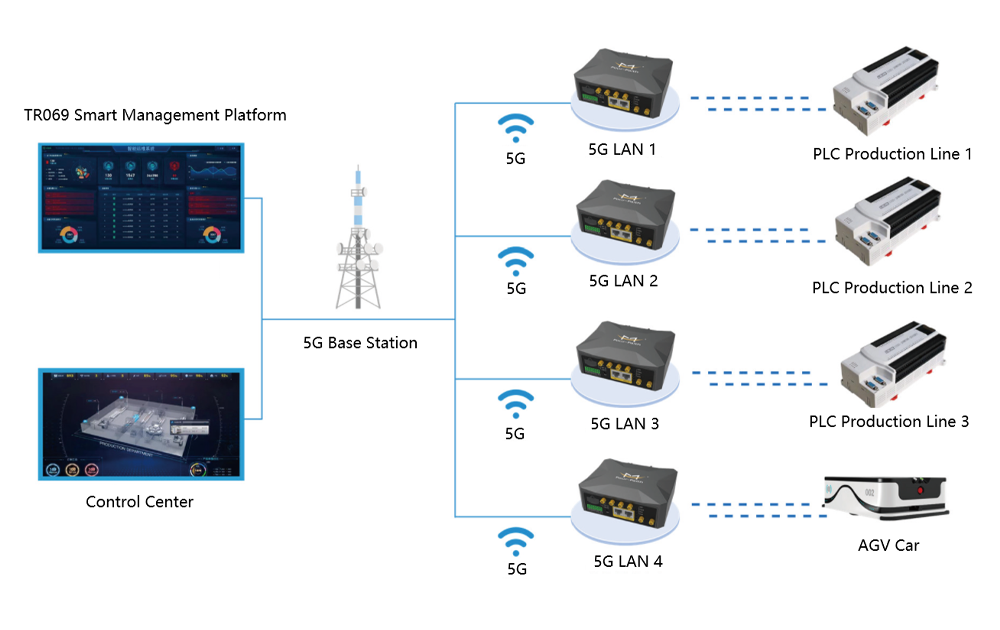

To address the current business continuity issues faced by traditional manufacturing companies, Four-Faith utilizes 5G networks to build 5G LAN, providing Ethernet local area networks for industrial control and other fields. This reduces local exchange communication latency and enables industrial Ethernet access without the need for AR routers to perform L3 to L2 conversion, significantly reducing the complexity of networking and deployment.

The Four-Faith 5G Full-Connected Factory solution is based on emerging technologies such as 5G private networks, 5G LAN, and IoT platforms. It combines the development concepts of automation, informatization, intelligentization, and digitalization to empower intelligent applications in various industries and scenarios in the IoT field. Examples include predictive maintenance of equipment, intelligent logistics, and flexible production lines, enabling the transformation of traditional factories into intelligent factories through 5G+ upgrades.

The entire project involves the deployment of a 5G private network by the network operator, with Four-Faith 5G industrial terminal products connecting to the private network. Through 5G LAN's Layer 2 interconnection technology, remote servers can directly access on-site PLC devices for real-time data acquisition and control. Additionally, the project gradually integrates 5G with core business operations by building 5G network infrastructure, establishing a 5G data platform, performing industrial modeling and analysis, and transforming existing businesses into the cloud. This promotes the integration of 5G with factory production, drives the transformation of production and operation models, and enhances the level of factory intelligence and management efficiency.

The Four-Faith 5G Full-Connected Factory application solution consists of four main components, including terminal devices, communication equipment, comprehensive business application platforms, and TR069 device management platforms.

System Composition

Terminal Devices

Various models of PLCs installed inside the machine tools, used for functions such as mechanical manufacturing, sensor interaction, and information processing of high and low voltage products.

Logistics carts.

Communication Equipment

The communication equipment mainly consists of Four-Faith F-NR100/F-NR120/F-NR130, which can be adapted to different sizes of 5G products based on the space of different terminal devices. It transmits PLC data through the operator's 5G private network and uploads it to the comprehensive business application platform.

Comprehensive Business Application Platform

It mainly consists of servers and software, which receive PLC data transmitted from the communication equipment and analyze and process it to effectively monitor and control equipment operation.

TR069 Device Management Platform

Four-Faith offers multiple 5G products integrated with the TR069 protocol, allowing remote maintenance, configuration changes, parameter queries, alarms, remote upgrades, and more on the communication equipment through the TR069 platform.

Solution Advantages

Data-driven

The solution utilizes 5G LAN technology to achieve efficient interconnection of information between devices. Operators can collect dynamic production data of production equipment, materials, finished products, etc., to timely grasp the production operation status. This seamless integration between the production environment and the information system enhances on-site perception and monitoring capabilities, meeting the demand for 24-hour factory monitoring.

Integration

Establishing an enterprise information integration platform enables seamless connection of upstream and downstream data, supporting overall enterprise management and highly integrating real-time data from the production process. This forms a complete and reliable production chain, ensuring availability and controllability of plans, transparent plan execution, controllable production cycles, and improved utilization of equipment resources.

Visualization

Real-time control of the equipment production process ensures stable and controllable product quality. At the same time, it enables data visualization on large screens, timely warning of abnormal issues, allowing administrators to discover problems and adjust production plans promptly, enhancing decision-making for enterprise management.

Product Recommendation

The Four-Faith 5G series industrial routers all support 5G LAN technology, providing both L3 layer IP services and L2 layer LAN services, effectively isolating business, and management functions. With the 5G LAN feature, these routers offer high-speed and stable network access for remote devices, enabling more efficient data interaction between terminal devices and platforms. They meet the demands for high speed, ultra-large connections, ultra-low latency, and secure transmission.

Moreover, 5G LAN technology has significant advantages such as plug-and-play, cross-domain networking, and network determinism, making it highly applicable in areas like industrial PLCs and park network infrastructure. Four-Faith's 5G industrial routers equipped with 5G LAN technology not only reduce the costs of building industrial Internet networks but also simplify the transformation of production lines and maintenance of industrial Internet. They provide flexible adaptability, ultimately greatly improving production efficiency.

Applications

TAGS: 5G Full-Connected Factory 5G Industrial Routers [Previous Page]

Previous Page:Automated Control and Monitoring Solution for Port Crane based on F-NR100

next page:Four-Faith 5G RedCap Application Solution, Accelerating Towards the Vast Ocean of 5G Smart Factories