RECOMMEND SOLUTIONS

RELATED PRODUCTS

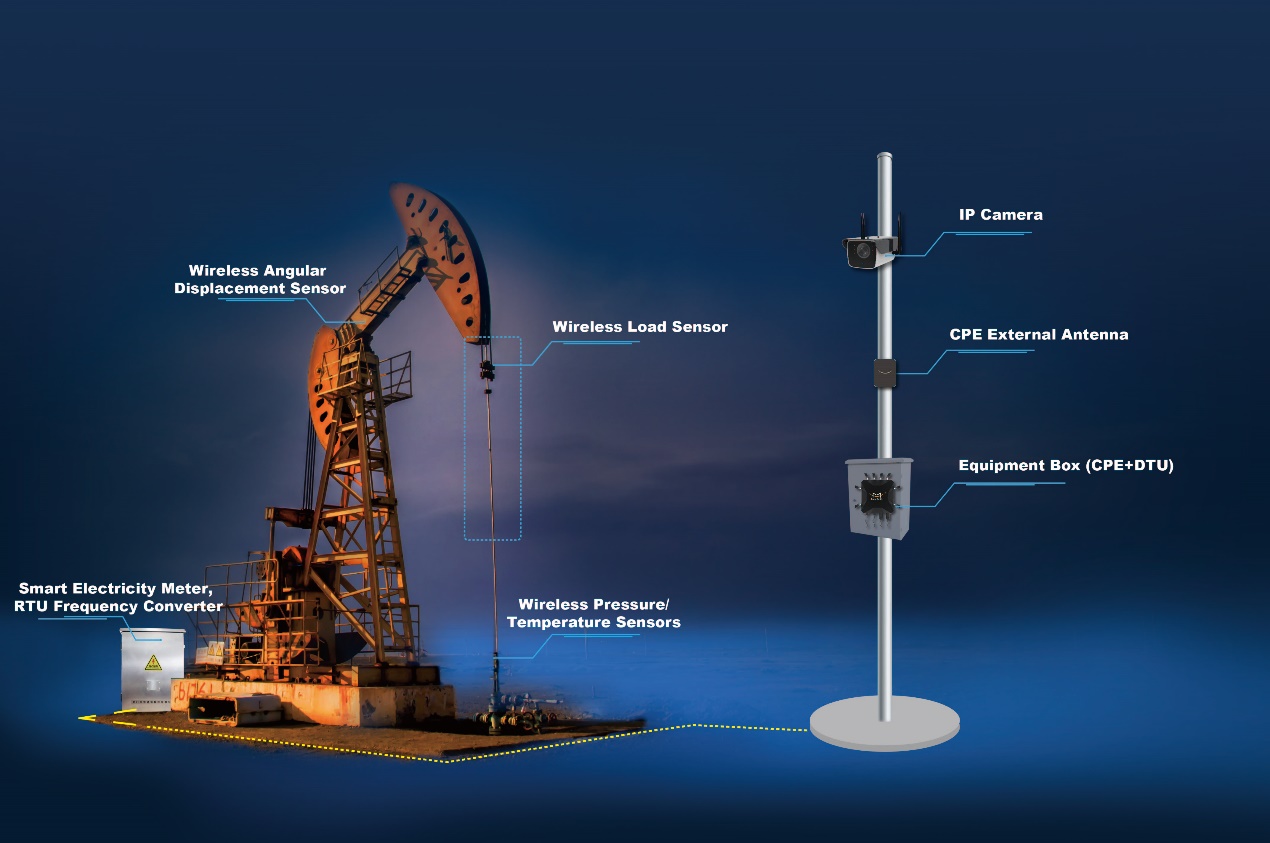

Networking for the Oil Well and Gas Industry

Date:2011-01-06 16:55:00

Background

An automated oil tank monitoring system is designed to gather information, including oil level and temperature, and handle the security system at an oil tank farm. The system is centralized, which means that less manpower is required and it is much easier to manage and collect information. Since the system is set up to provide real time management, the operators can enjoy a higher level of security and ensure a much faster reaction time in case of emergencies. In addition, since monitoring is more accurate, oil companies can avoid the oil waste generally inherent in storage and transmission.

Project analyse

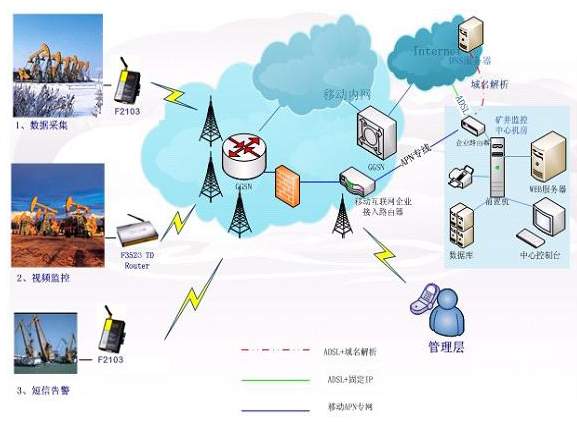

Oil Well’s collection terminal’s connection through RS232/485 serial port and F2103’s serial port, data monitoring centers can connect to the network using a variety of ways, such as fixed IP, APN, ADSL and so on.

The connection between GPRS network and Remote data center server host by F2103 GPRS IP MODEM, to open the transparent data channel after establishing TCP/IP with center.The data will transferred by serial port to data center server host if required; When the data center or data commands issued through the channel after the transfer to the F2103, The data will be transferred via F2103’s serial port to the collection terminal, to realize to transfer the data transparently.

An automated oil tank monitoring system is designed to gather information, including oil level and temperature, and handle the security system at an oil tank farm. The system is centralized, which means that less manpower is required and it is much easier to manage and collect information. Since the system is set up to provide real time management, the operators can enjoy a higher level of security and ensure a much faster reaction time in case of emergencies. In addition, since monitoring is more accurate, oil companies can avoid the oil waste generally inherent in storage and transmission.

Project analyse

Oil Well’s collection terminal’s connection through RS232/485 serial port and F2103’s serial port, data monitoring centers can connect to the network using a variety of ways, such as fixed IP, APN, ADSL and so on.

The connection between GPRS network and Remote data center server host by F2103 GPRS IP MODEM, to open the transparent data channel after establishing TCP/IP with center.The data will transferred by serial port to data center server host if required; When the data center or data commands issued through the channel after the transfer to the F2103, The data will be transferred via F2103’s serial port to the collection terminal, to realize to transfer the data transparently.

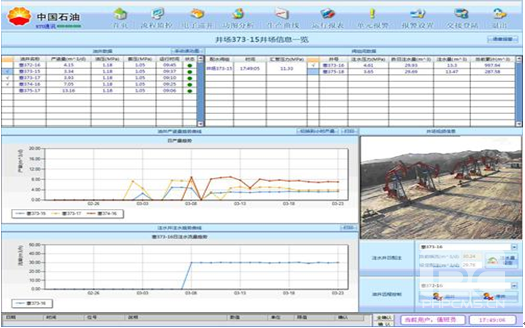

2.3 The achieve function in System

1, the data detection function: automatic monitoring, record oil production equipment, the voltage, current, power, temperature, pressure, flow, level, interface, moisture, indicator diagram, infrared alarm data. Data collection format for analog, digital, and serial communication port. Can complete the degree of traffic and integrating power.

2, data sharing: the measured data and the working status of production equipment can be transferred to the LAN, the realization of multi-party remote data sharing.

3, display: total flow display, group process showed that all the data list, a list of packet data, a single instrument list of historical data for the day, month, year display, fault list displayed.

4, secondary analysis: to detect power failure, phase, tubing plug, Stolen, liquid level is too low, abnormal weight imbalance.

5, the alarm function: If the test value exceeds the setting range, the sound and light alarm, and to problems with the screen name and parameters of the instrument beyond the scope, if multiple data alarm list will be displayed in the order value.

6, permissions settings: general permission settings sub-operators, administrators, three super-systems management. Enter the user name and password used to restrict

2, data sharing: the measured data and the working status of production equipment can be transferred to the LAN, the realization of multi-party remote data sharing.

3, display: total flow display, group process showed that all the data list, a list of packet data, a single instrument list of historical data for the day, month, year display, fault list displayed.

4, secondary analysis: to detect power failure, phase, tubing plug, Stolen, liquid level is too low, abnormal weight imbalance.

5, the alarm function: If the test value exceeds the setting range, the sound and light alarm, and to problems with the screen name and parameters of the instrument beyond the scope, if multiple data alarm list will be displayed in the order value.

6, permissions settings: general permission settings sub-operators, administrators, three super-systems management. Enter the user name and password used to restrict

3.3 Establish the data center software

There are many kinds of way to establish the data center software,Regarding the different way to transfer the data,we can offer different software to help customer realize the data management;

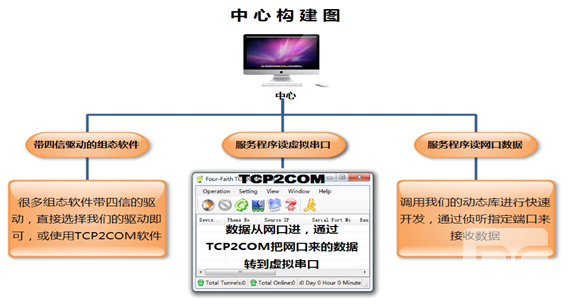

There are three ways for center interface,pls refer to the following:

Following is the Central management software:

Project Feature:

1, It is low cost and convenient to use GPRS network to transfer the data,which solve the distance issue; and gprs modem is very small and flexible;

2. F2103 IP MODEM used industry standard serial communication, plug and play, without too much expertise and knowledge,complete the operation quickly, and the high standard mold design, small size, easy to maintain.

3. Oil field equipment are working for the day and night, and the local environment and climate are relatively poor, but it is required to keep always monitoring , our high-performance industrial grade IP MODEM’s processor, watchdog,and other security mechanisms designed,which to ensure IP MODEM will be self-testing once communication interruption, then automatically power off restart, ensuring always-on line, and the communication link is always normal.

4, Multicenter design, which can set up five centers collected on monitoring site,to avoid the instability of a network of centers, or closing of the mine site can not be monitored and a security risk.

5. High-standard materials matching, can work -25 ~ +65 º C, relative humidity of 95% (no condensation).

6, Support Multi-protocol, and transparent TCP,UDP protocol,to offer the client’s more options;

TAGS: Gas Industry Oil Industry Oil Industry application [Previous Page]

Previous Page:first_page